Welcome to Week 5 of National Safety Month 2025

Proudly Sponsored by:

Safety isn’t just a buzzword for us at Jabiru—it’s how we’ve built our reputation as Australia’s most successful aircraft manufacturer. With over 2,000 aircraft and 7,000 engines flying worldwide, we’re proud to sponsor National Safety Week because we know our fleet has one of the best safety records in Light Sport Aviation.

We’re backing that up with real action. Our manuals and resources are readily available. Always. Operation Bulletproof, our approved maintainers and owner courses, and revamped service notices are designed to keep you flying safely and confidently. When you call us, you’ll talk to a real person, with unmatched parts availability and support you can count on.

When we say “Air. Craft.” we mean it: we’re here to keep you flying safely, affordably, and confidently, backed by 37 years of Australian innovation and a track record that proves we’ll support your aircraft and engines for decades to come.

Find out more: https://jabiru.aero/

Flight Phase: Post-flight activities

As we conclude our flight and our journey through National Safety Month 2025, there are a few important aspects that we must consider making sure our flight was completed to the best of our ability. We, now, turn our focus to some equally critical aspects of aviation safety:

Post-flight debrief and actions to analyse how we handled our flight, from start to finish. As discussed in last year’s National Safety Month content, post-flight reflections/analyses can help us understand what may not have gone to plan, but also what went as planned prior to the flight.

Every single flight offers invaluable lessons, which we can only appreciate if we take the opportunity to sit back and reflect. In the process, remember to consider: Flight plan adherence, Situational Awareness, Decision making, Emergencies – preparedness & actions, Communications, and Aircraft handling.

In regard to continuing airworthiness after the flight, did we observe any defects, reduced functionality or have a hard landing that needs documenting and further maintenance actions

👉 Recreational pilots are essentially self-regulating in how we conduct our flight activities, so an honest and practical debrief after each flight is essential to take forward important lessons and for a chance to recognise both our strengths and weaknesses in order to continue to have safe flying outcomes.

Aircraft maintenance. This week we look closely at maintenance practices from technical documentation, to release to service forms and typical maintenance actions including scheduled maintenance activities that ensure our aircraft remains airworthy.

With guidance from both our Head of Airworthiness and Maintenance and our week 5 sponsor, Jabiru Aircraft, we walk through some typical maintenance tasks to learn how the pro’s do it.

So just like in our flight operations , we are also drawing a connection to our first week’s content in week 5 – HUMAN FACTORS. However, this time, we shift our focus towards maintenance practices and the human factors associated with aircraft maintainers. Aircraft maintainers do a commendable job in prepping these wonderful machines to ensure a smooth and safe journey. However, in doing so, there’s one element that’s often overlooked in the busy hangar environment – MAINTAINER HUMAN FACTORS.

Finally, in National Safety Month, it’s only complete if we talk about Aviation Safety Management System (SMS) and its relevance for small aircraft operators – LIKE US!

Occurrence and defect reporting forms a critical part of the overall Aviation Safety Management System (ASMS). Our role as operators, pilots or maintainers feeds this critical information in an open and fair reporting culture that drives the assessment and mitigation of potential safety issues.

👉 Implementing a robust and relevant ASMS covers all the significant aspects of aviation safety – including those discussed over National Safety Month 2025 and beyond.

Maintainer Human Factors

The ‘human factor’ has most commonly been associated with pilots as we discussed the ‘IMSAFE’ mnemonic for pilot risk management through our week 1 content. However, Human factors and IMSAFE applies to maintainers to the same degree as pilots. An area of further focus in human factors for maintainers is the point of ‘not admitting limitations.

Aircraft maintainers are known for their “Can Do” attitude, which motivates them to do exceptional work despite all the challenges. However, this mentality can backfire at times.

💡 Think about these statements:

“I have not been properly trained on this, but I have so much experience, I can figure out how to do the task without any training or supervision.”

“How hard can it be? I have a Maintenance Authority / Licence after all. That proves I can do it.”

“Sure, I can take care of those as well!” “I’m tough! I can work 10 hours every day, month after month without much sleep. I’ll sleep when I die!”

Not admitting limitations!

Not admitting limitations highlights that everyone has their limits. The study of human performance limitations is a vital part of human factors training. We must understand, be honest, transparent, and assertive by admitting our limitations in order to perform our tasks effectively and safely. Exceeding our limitations decreases performance, increases risk to the individual and colleagues, and may lead to aircraft and equipment damage. The counter measures to “not admitting limitations” include:

- Be aware of your physical, cognitive, and technical limitations

- Listen to your body’s warning signs

- Letting go of your ego

- Admit lack of knowledge

- Always follow the correct procedures

- Seek answers and ask for help

- Take breaks and live a healthy lifestyle

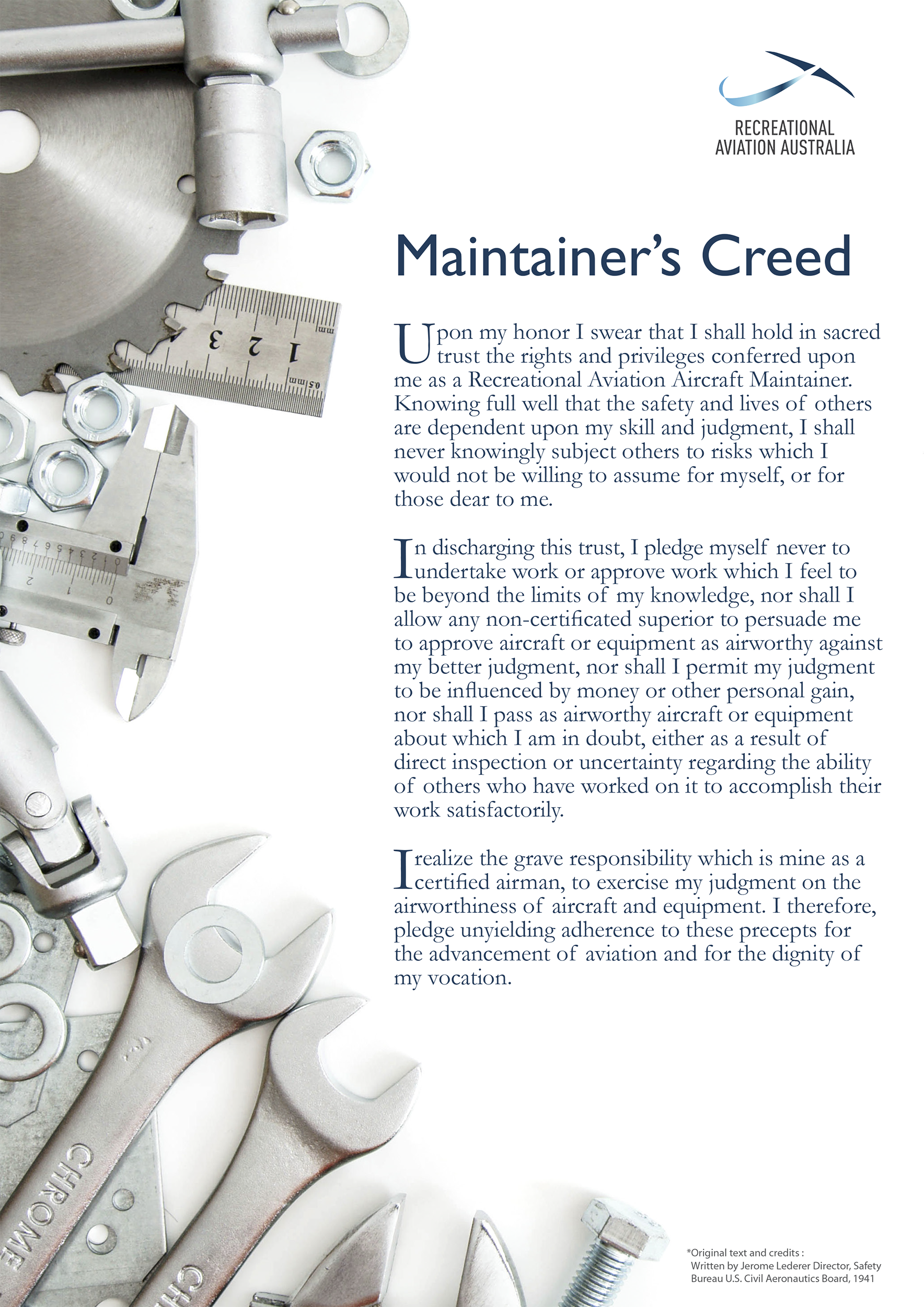

Maintainer’s Creed

Doctors in many Western countries take the Hippocratic Oath upon entering the profession, as a symbol of their commitment to upholding a number of ethical and moral standards. In the aircraft maintenance world, maintainers live by the ‘technician’s creed’, which was originally written by Jerome Lederer in 1941. The creed appeared on the back cover of the first issues of Flight Safety Foundation’s Aviation Technicians Bulletin in 1953 and proved to be extremely popular. Maintainers around the world wrote to request copies of the creed to hang in their offices and shops. RAAus has used this creed (although slightly modified) to send to all new and renewing Level 2 maintenance authority holders to promote a positive safety culture and to empower maintainers to admit their limitations. See the creed below.

![]()

![]()

Maintainer’s Checklist

Aviation authorities around the world have produced tried and tested personal minimums checklists for maintenance personnel to further assist in identifying limitations and as a means of quality control. See below and download a checklist for your use today!

Before you begin the task

Ask yourself the following:

- Have I had the proper training?

- Have I done this before?

- Do I have the knowledge I need?

- Do I have the technical data I need?

- Do I have the proper tools and equipment I need?

- Am I mentally prepared?

- Am I physically prepared?

- Have I taken the proper safety precautions?

- Am I authorised to perform the work?

- Have I researched the Regulations, airworthiness directives and service bulletins to ensure compliance?

After the task

Ask yourself the following:

- Did I perform the task to the best of my abilities?

- Did I perform the job task without pressure, stress and distraction?

- Did I perform the task using appropriate data?

- Did I use all the methods, techniques and practices acceptable to the industry?

- Did I or someone else re-inspect my work before returning the aircraft to service?

- Is the result equal to or better than the original design?

- Did I accomplish and record the required “independent checks” of affected controls?

- Did I record proper entries for the work I performed?

- Did I perform operational checks after the work was complete?

- Am I willing to sign off for the work performed?

- Am I willing to fly in the aircraft once it is approved for return to service?

Aircraft Maintenance – Good Practices

Preflight and Daily Inspection

In week 1 of National Safety Month 2025, we touched upon the importance of a pre-flight walk around inspection and some good techniques that we can deploy to ensure we get the process right.

Below, our week 5 sponsor, Jabiru, have provided some great “how to” videos for this week’s content. The recordings revolve around some of the important aircraft maintenance practices – worth exploring and reflecting on your maintenance actions against industry best practices!

Completing Aircraft Maintenance documentation

In week 1 of NSM 2025 “Checking the Paperwork” we looked at this in the preflight planning stage and Just like the aircraft preflight, any maintenance activity should start and finish with the paperwork. Entering maintenance issues, unserviceabilities or defects in the aircraft Hours and Maintenance Record (HMR Tech Form 121) or similar release to service document such as a CASA Maintenance release are acceptable documents for this purpose.

Being able to identify past and current maintenance activities, time requirements and gaining reference insights into particular components of an aircraft’s operational history are valuable markers that will ensure any activity undertaken is conducted with a full awareness of what has happened, any recurring issues and what specific directives or maintenance items need attention.

💡ATSB reports often highlight lapses in defect recording practices to contribute to aircraft accidents & incidents.

This short video takes us behind the scenes into the vital world of maintenance releases. It walks through the procedures, documentation, and responsibilities involved when a maintenance task is signed off. Whether you’re a maintainer, inspector, or aircraft owner, it reinforces how a formally recorded release helps ensure that every aircraft returns to service safely and compliantly.

Oil and Filter Changes

👉 Oil and filters: small parts that make the biggest difference!

One of the more basic regular maintenance activities that pilots and maintainers can undertake is the oil change. Oil and other fluids are the lifeblood of your engine, changing these regularly and the associated hardware like filters that clean these fluids is vital for ensuring continuing reliability and longevity of your engine.

But remember, this also includes any other fluids and the hoses that carry them that may be unique to your aircraft type. In the video below, experts discuss how crucial is it to replace oil and oil filter for the aircraft engines to function safely and efficiently.

Jabiru’s experts demonstrate the proper procedures for changing oil and oil filter on a piston aircraft engine (Jabiru aircraft), and highlight the key safety checks, best practices and standards to ensure this routine maintenance task is done correctly.

Scheduled Maintenance

What makes driving a car on a highway different from flying an aircraft? The answer is simple: the Third Dimension. In the air, there are no rest stops or breakdown lanes; your safety depends entirely on how well you and your aircraft are prepared for the journey.

Maintenance schedules are the contract by which you and your aircraft manufacturer, or a generic set of industry standards are applied to ensure your aircraft remains airworthy and safe. Scheduled maintenance looks specifically at two axes inspection and replacement. 1. The number of operational cycles or hours of use, and 2. Calendar time. Both will be unique to any aircraft type and often different for engines, airframes , propellors and other systems.

Finally, and often overlooked is time- life limitations on both full systems, like engines but also components and even airframes. Scheduled maintenance ensures your aircraft is fit for flight and helps prevent mechanical surprises once you’re airborne.

In the short video below, Jabiru’s experts explain the importance of scheduled maintenance, including required documentation, inspection frequencies, and the reference materials you should use during each task.

💡Remember: If you miss the scheduled maintenance as recommended by the manufacturer, you risk losing your insurance cover!

Staying current with your maintenance schedule keeps you compliant, protected, and most importantly, safe.

Replacing tyres or wheels

👉 If I have a flat tyre, well, what do I do?

Am I allowed to change aircraft tyres myself?

Where do I find the instructions to perform an aircraft wheel change?

It’s an annoying task with a car, but changing a tyre or tube on an aircraft has additional complexities from jacking procedures to splitting hubs. Having the correct tools and following the manufacture procedures is imperative to ensure safe and effective replacements that won’t cause any further damage. The following video highlights the steps involved in the aircraft tyre change procedure.

It also answers the above questions, while emphasising recommended good practices for a quality and efficient tyre change process.

- Aircraft jacking – standard & safe practices,

- Tools required,

- Removing tyres from the aircraft,

- Replacing the tubes (including, deflating the tube, removing brake disc, detaching the rims,

- Reinstalling tube in the tyre, followed by the rims and the brake disc,

- Inflating tyres, and

- Installing tyres on to the aircraft.

Leak Down and cylinder compression Test

👉 Leak Down Test – The window into your engine itself!

All aircraft components wear, and this cannot be clearer that the highly stressed parts of a reciprocating Internal Combustion engine. Many factors can affect the natural process of metal-on-metal surface operations but the leakdown test gives a critically important insight into the condition and performance of every cylinder in our aircraft engine.

The RAAus Head of Airworthiness and Maintenance says: When reviewing many engine failure or malfunction occurrences that resulted in aircraft landing in paddocks, we’ve observed a common trend, which was a leak-down test had not been performed on those engines. In most cases, the evidence suggests that if a proper leak-down test had been carried out, many of these incidents could have been prevented.

Review this video by Jabiru, that highlights not just the importance of a leak down test but also the steps involved.

Safety Management System

👉 Safety management is not just a back-office task!

It is a front-line tool that shapes how we fly, how we train, and how we prevent accidents in the future.

SMS scope

Every organisation is different: whether you’re a solo operator, a small flight training school (FTS) with a close-knit team, or a large FTS managing busy airspace. Your Safety Management System (SMS) should be right sized for your operation i.e., simple where it can be and structured where it must be.

No matter their size, all organisations, large or small, complex, or non-complex, share the same four basic SMS components.

- Safety policy and objectives

- Safety risk management

- Safety assurance

- Safety promotion.

There are also two factors that are fundamental to the success of an SMS for all organisations regardless of size or complexity – management commitment and responsibility for safety and a positive safety culture or ‘Just Culture’.

For the Solo Operator

Running a one-person band? Your SMS can be clear and compact:

- A short safety policy

- A risk journal or simple log for observations

- A basic risk profile

- A quick-reference emergency plan

Everything can live on your iPad or in a single folder and that’s perfectly fine. What matters is that “it works and you use it”.

For the Small Team

As your operation grows, your SMS grows with you. Add:

- Simple reporting tools

- Regular safety reviews

- A shared hazard register

- A more detailed emergency response plan

Keep it lean, but make sure your team is engaged and everyone knows their role.

For the Large FTS

Staying current with your maintenance schedule keeps you compliant, protected, and most importantly, safe. In a bigger school or complex airspace, structure brings consistency.

- Formal documentation and version control

- Safety committee meetings

- Data analysis and trend monitoring

- Comprehensive risk management processes

These help maintain oversight and confidence as operations expand.

Takeaway

Safety management isn’t about ticking boxes, it’s about building a culture of awareness and accountability. A well-fitted SMS helps prevent incidents before they happen, supports your decision-making, and builds trust with your students, instructors, and the flying community.

👉 Start small, grow steadily, and keep it relevant.

You have to be in it to win it!

Don’t forget to revisit and read all of the content from the five weeks of National Safety Month 2025! Engaging with this material will give you the chance to enter our exciting prize draws.

Keep in mind that all entries for the prize draws will close on 2 November 2025, so make sure to participate before the deadline. Don’t miss out on your opportunity to win amazing prizes while enhancing your knowledge about safety!

PARTICIPATE TO WIN!

Read and watch the content above, then enter your details and the hidden code word to enter our Week 5 prize draw!

YOU COULD WIN ONE OF THE FOLLOWING PRIZES*

FIRST PRIZE: Jabiru Maintenance Course

Sponsored by Jabiru

Valued at $2,500

SECOND AND THIRD PRIZE: FLYTE Sunglasses

Sponsored by FLYTE

Valued at $245 each

*Applicants must hold a current Flying Membership or Non-Flying Membership in order to win the first and second prize.

*Terms and Conditions apply